- Introduction

Introduction

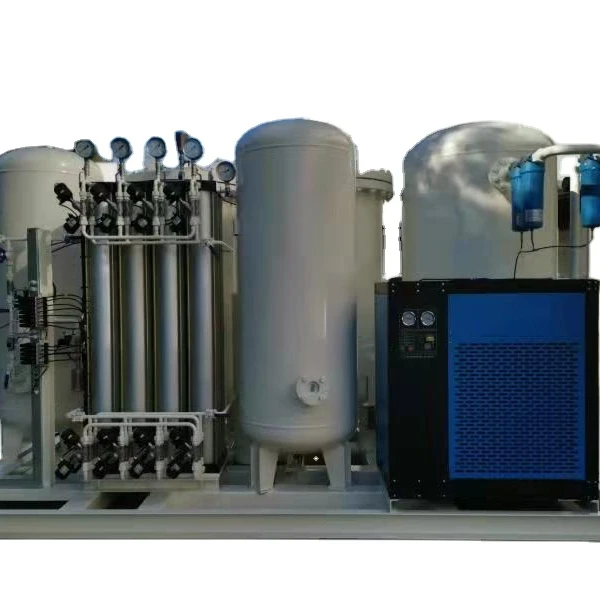

The oxygen producing unit, using the imported UOP molecular sieve, has the characteristics of strong relative water resistance, long service life and so on. It is widely used in the medical industry of PSA oxygen making machine.

(1) a medical grade PSA oxygen producer based on the registration of the State Administration of drug administration.

(2) all the main components, such as molecular sieve, valve, PLC and other main components, are all imported.

(3) the oxygen making unit adopts the modular assembly way, which is convenient for the disassembly and replacement of the later stage.

(4) small volume and weight: smaller and more flexible than traditional oxygen making machines.

(5) longer life: the core part of the molecular sieve oxygen maker is molecular sieves, and molecular sieves will gradually reduce their performance during a long and continuous use process.

(6) low failure rate: all the main components are imported. After years of application, the reliability and optimized process flow are verified, reducing unnecessary valves and reducing failure rate.

(7) convenient maintenance: more integrated structure, reduce the need to maintain the components, more convenient to complete the replacement and inspection of parts.

Details

Use of ambient temperature

Temperature: -45 C- 50 degree C

The relative humidity is less than 93%

Product model DEBAISHI SUNNIC10-60L

Oxygen supply flow 10-60L

Oxygen concentration 93%

Power 220V50HZ

Noise 70dB

The rated power is less than or equal to 3500

Shape size 1120MM x 736MM x 1432MM

FAQ

1. Are you manufacturer or Trade Company?

We are oxygen machine factory, founded in 1997.

2. What's the order Enery-Saving and high efficiency oxygen machine Process?

a. Inquiry---provide us all clear requirements.

b. Quotation---official quotation form with all clear specifications.

c. Printing file--- PDF, Ai, CDR, PSD, the picture resolution must be at least 300 dpi.

d. Contract confirmation---provide correct contract details.

e Payment terms--- T/T 30% in advanced, balanced before shipment.

f. Production---mass production

g. Shipping--- by sea, air or courier. Detailed picture of package will be provided.

h. Installation and commissioning

3.What terms of payment you use?

T/T, L/C etc.

4. How to get a prompt quotation of Enery-Saving and high efficiency nitrogen filling machine ?

When you send the inquiry to us, pls kindly send it with below technical information.

1) o2 flow rate: _____Nm3/hr

2) o2 purity: _____%

3) o2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Applicatio

Introduction.

SUNNY YOUNG Systems have a range of PSA nitrogen & oxygen generators, membrane nitrogen & oxygen generators, nitrogen purification systems etc, and are widely used in industries of petroleum, oil & gas, chemicals, electronics, metallurgy, coals, pharmaceuticals, aerospace, autos, glass, plastics, food, medical treatment, grain, etc. With years research in air separation technology and rich solution experiences in various industries, SUNNY YOUNG sticks to providing our clients with more reliable, more economical, more convenient professional gas solutions.

We have an experienced professional team always ready to be at your service. The sales engineers carefully analyze your specified requirements and offer suitable solutions for you. The after-sale service system guarantees swift response to your problems within 24 hours and their resolutions in the shortest time. SUNNY YOUNG is responsible for after-sales services to nitrogen/oxygen generators and other related equipment offered by us.

SUNNY YOUNG is dedicated to supplying with our customers with more reliable, more economical and more convenient air separation solutions and professional service.